"BLCKSTRM" (BLCKSTRM)

"BLCKSTRM" (BLCKSTRM)

04/28/2016 at 13:37 • Filed to: Tesla, Finance, Big 3, Innovation, Engineering

6

6

12

12

"BLCKSTRM" (BLCKSTRM)

"BLCKSTRM" (BLCKSTRM)

04/28/2016 at 13:37 • Filed to: Tesla, Finance, Big 3, Innovation, Engineering |  6 6

|  12 12 |

I get it.

Elon Musk is a genius.

Please don’t think I’m being sarcastic - you look at what he’s done with PayPal, Tesla, and SpaceX. It’s light years beyond anything we normal humans could accomplish.

But I think David’s article !!!error: Indecipherable SUB-paragraph formatting!!! misses the mark by painting established auto OEMs as a bunch of whiny, jealous doubters.

!!! UNKNOWN CONTENT TYPE !!!

Disclaimers: Like David, I’ve worked at the Big Three (I worked at GM in a corporate strategy team for two years). If it helps assess my sentiment, I got laid off when they went bankrupt. I also worked for Samsung for 5 years following that, again doing corporate strategy and competitive intelligence.

So, I think that gives me a pretty balanced view of what’s going on here and why I think it’s so hard for them to see eye-to-eye. And also explains in particular why former-GM’s Jon Bereisa overestimates Tesla’s engineering and production costs.

The TL;DR version is that for better AND worse, the two camps are starting from different points of view.

Tesla doesn’t have decades of class-action lawsuits and recalls to drive it to over-engineer (and spend years validating) its vehicles. It also has extremely patient consumers who are comfortable with the uncertainty - and headaches - that go along with being an early adopter of unproven technology.

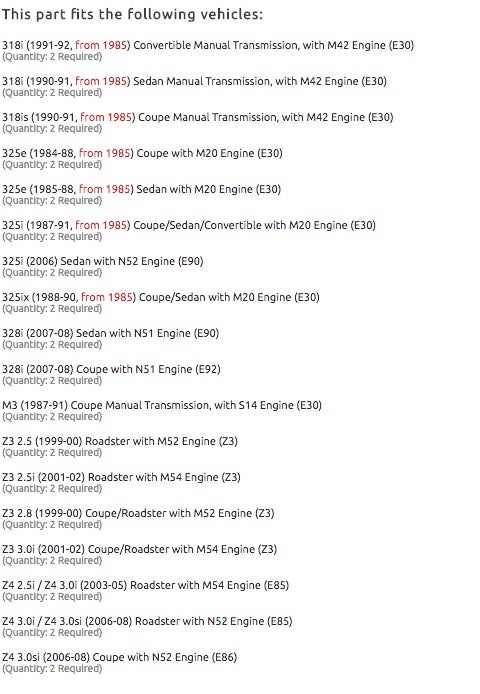

Anyone who’s spent time replacing parts on old cars knows which parts you can get cheap at the local parts store and which parts you need to get from the OEM (or at least the OE supplier).

Even more, OEMs know where they can save money on parts and where they need to spend money. Even then, sometimes saving money is re-using tried and true parts instead of something cheaper, like this wheel bearing example I stumbled across (I don’t own anything this bearing fits. Why was I looking at it? Because I’m sick...)

Right now, Tesla is young enough as a company that it doesn’t have that information, so it seems like they just went cheap on everything and are seeing what breaks and where they need to spend more money next time around.

One analysis indicates that as many as

!!!error: Indecipherable SUB-paragraph formatting!!!

by the time they hit 60k miles. There are

!!!error: Indecipherable SUB-paragraph formatting!!!

.

!!! UNKNOWN CONTENT TYPE !!!

They also aren’t overbuilding (like the Big Three and other established OEMs) for the extreme use cases a relatively small percentage of consumers experience.

When I was at GM, someone who worked with Jon Bereisa told me they solicited a bid on Volt batteries from Tesla. When Tesla got the technical requirements (particularly the required temperature operating window), they told GM “that’s impossible.” GM then sourced the batteries from LG.

But Tesla obviously has had little problem with using batteries built to their own technical requirements. That huge difference in assumptions - and the engineering required to meet those assumptions - drives an incredible amount of cost.

Well, mostly little problems. Sometimes it doesn’t matter. !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

Obviously, it matters enough that Jon Bereisa was off by $70/kWh - or around $4,000 total cost - when estimating the Model 3's battery pack costs.

Luckily, Tesla consumers remain undeterred, aided by Tesla’s fantastic warranty and customer service practices. In fact, the pro-Detroiters would argue that Tesla’s awesome customer service is actually carefully calculated to pacify buyers despite the car’s less-than-stellar quality.

The real problem is that these issues hurt resale value, which matters because resale plays a huge factor in determining lease rates.

But Tesla has also mitigated this issue as well, by launching a !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

Another brilliant move by Musk, but again - fixing problems is more expensive move than avoiding them in the first place.

!!!error: Indecipherable SUB-paragraph formatting!!! Tesla’s ability to make the jump from the early adopter to the !!!error: Indecipherable SUB-paragraph formatting!!! .

!!! UNKNOWN CONTENT TYPE !!!

!!! UNKNOWN CONTENT TYPE !!!

While Tesla is still having !!!error: Indecipherable SUB-paragraph formatting!!! .

!!! UNKNOWN CONTENT TYPE !!!

All a long way of showing that Tesla’s “different” point of view looks a lot like ignorance / inexperience to many industry veterans, who see these problems as evidence Tesla is cutting corners.

While Tesla sees a lot of waste, groupthink, NIH syndrome, and “this is how my grandpa did it” mentality.

The truth is the two sides are unlikely to ever see eye-to-eye, but both are likely to make efforts to learn from what the other is doing to cut costs and increase innovation (in the case of the Big Three) or reduce warranty expenses and increase quality (Tesla).

jimz

> BLCKSTRM

jimz

> BLCKSTRM

04/28/2016 at 13:46 |

|

this is similar to what I said in the comments of David’s article. The existing automakers “get” Tesla just fine. they’re just operating under a lot more constraints than Tesla is now. Unfortunately most of the narrative about Tesla has been shaped by the tech press, which understands very little about cars (and the manufacturing thereof) and I’m a bit saddened Jalopnik seems to be taking the same tone.

BLCKSTRM

> jimz

BLCKSTRM

> jimz

04/28/2016 at 13:53 |

|

I had a huge discussion with a commenter last night /this morning, which drive me to write an actual article.

It’s like the autoextremist always says - you just don’t get it unless you’ve lived it.

And no offense to David, but it’s a far different thing to be a cog in an engineering department than to be working on the company strategy and taking with executives.

Mercedes Streeter

> BLCKSTRM

Mercedes Streeter

> BLCKSTRM

04/28/2016 at 13:54 |

|

TL;DR - Tesla is post-Jobs Apple, and The Big Three is Microsoft.

Both have their advantages (Apple’s aesthetics, Microsoft’s OS) and both have their faults (iPhones are fragile, Microsoft support is next to worthless).

Berang

> BLCKSTRM

Berang

> BLCKSTRM

04/28/2016 at 14:00 |

|

Superficially though, it looks lot like detroit’s early dismissal of makers like Volkswagen, Subaru, Honda, etc.

vondon302

> BLCKSTRM

vondon302

> BLCKSTRM

04/28/2016 at 14:00 |

|

Can you apply for the Jalopnik writing job. I know your probably over qualified but damn that was a good post.

BLCKSTRM

> Mercedes Streeter

BLCKSTRM

> Mercedes Streeter

04/28/2016 at 14:00 |

|

I’d go so far top say that Tesla is Steve Jobs Apple - and people buy the leader as much as the product.

BLCKSTRM

> vondon302

BLCKSTRM

> vondon302

04/28/2016 at 14:05 |

|

Thanks!

And I did, but for one of the part-time contributors.

(I may have taken the time to write this article just a little because they’re looking at the moment).

But thanks for the kind words!

BLCKSTRM

> Berang

BLCKSTRM

> Berang

04/28/2016 at 14:11 |

|

And that’s why I’m part of the crusade against hyperbole and knee-jerk reactions.

dsigned001 - O.R.C. hunter

> BLCKSTRM

dsigned001 - O.R.C. hunter

> BLCKSTRM

04/28/2016 at 22:18 |

|

While I think, at a fundamental level, I agree with everything you said, I do disagree in some of the details.

dsigned001 - O.R.C. hunter

> BLCKSTRM

dsigned001 - O.R.C. hunter

> BLCKSTRM

04/28/2016 at 23:16 |

|

While I think, at a fundamental level, I agree with everything you said, I do disagree in some of the details.

Firstly, I think it’s probably important that I acknowledge that, in part at least, the big three are the product of a regulatory environment that’s fairly hostile, and a market that’s deceptively competitive. So, like a child raised in an abusive home, I don’t think it’s particularly surprising that they’re as dysfunctional as they are.

With that said, I think you may have an overly rosy view of the big three in terms of their build quality, and a fantastically rosy view of the auto industry in general. Having worked on “old” GM products (2004), I’ve not been impressed with the build quality or design on a great many things on the car.

So, from the standpoint of Tesla, while it’s likely true that the build quality is lower in some things than one of the big automakers, it’s also true that automakers like BMW, Jaguar and Land Rover are every bit as terrible.

I also agree that it’s one thing to market to the early adopter, and quite another to market to the mainstream. But personally, I think the comparison to Apple is apt. Not because Musk has the Messiah aura that Jobs did (though I think he’s coming pretty close), but because he has a much better sense of what the consumer is looking for than his peers in the auto industry, most of whom are career executives and all of whom are his senior by a decade or more. When you compare Jobs in the 90's, Jobs of the iPod and Jobs of the iPhone especially, I think that his genius is obvious in hindsight. But really, I think part of it is damning of the way corporate leadership is selected. There’s no way in hell that Musk or Jobs could have come to power through the rank and file, or allowed to continue on as CEO through some of the risks they’ve taken. As workers, they would have been entirely too polarizing, would have made enemies, and been relegated to head of “product development”, much like Lutz was at BMW, Ford, Chrysler and GM.

The point is, I think you’re wrong about Tesla, long term. But more to the point, I think you’re wrong about the big 3. The way I see it, the problems in the management of large American corporations has reached the level of an epidemic. The number of US corporations that have either gone bankrupt, sold out, or have become seriously scummy in the past 20 years is “most of them.” The companies that haven’t run in to major issues are mostly those being run by their founders.

BLCKSTRM

> dsigned001 - O.R.C. hunter

BLCKSTRM

> dsigned001 - O.R.C. hunter

04/29/2016 at 14:33 |

|

I’m not sure what’s “deceptively competitive” about the auto market. The OEMs have been involved since the invention of auto racing trying to find any advantage they possibly could.

Moreover, patent protection in the industry is pretty weak. It takes roughly 5-8 years to develop a car and they stay in production for about the same amount of time. You get 20 years from the filing date for patent protection, so you only really get two generations of vehicle before your competitor can start copying you legally.

It’s always been intensely competitive.

But your comments about the regulatory environment are spot on. I think this acknowledgement of the role the regulatory environment has played in shaping the industry is too often ignored, and is one of the keys in understanding why people from the Big Three are caught with their mouths hanging open. It’s not that Tesla could do something from a technical perspective - it’s usually shock they did something from a liability perspective.

I’m still waiting for that to bite them, but it may not. Things are changing. For example, progress on automation (even just that first step of automated braking and lane keep assistance) is helping avoid accidents that could have been blamed on Tesla’s “distracting” 17" display that lets you browse and drive. So go ahead and BE distracted - Tesla has your back.

This particular issue has been a huge point of concern for existing OEMs for years - and it seems like Tesla didn’t even think about it, they just did it.

So they look slow and backward - until Tesla gets sued by an accident victim. (which, again, this being America - I’m dumbfounded this hasn’t happened yet). But if the lawsuit never comes, the rest of the industry is just left holding a bag of “what if?”

I’d love to have a discussion about the leadership situation. There is a lot of merit in what you’re saying, and it affects every organization. Tesla has a strong enough following (and frankly, enough Model 3 pre-orders) that they’ll stay in business long enough to figure out the things they don’t know or are doing wrong. And I also won’t discount the value to them of hiring refugees from the Big Three. They’ll continue to get better. The Model X is only the third vehicle they’ve even launched - experience can only help.

I think the battery piercing issue is particularly instructive. They made a decision, and when it bit them they were relatively quick to address the issue. Some of the criticism of that issue was that they should have caught it during validation, but the argument was that their validation program wasn’t as a robust as traditional OEMs (and not confined to Tesla - Toyota also got in trouble in the late 00's for shortening their validation cycle to speed up their time-to-market).

But as with anything, there’s no guarantee they’d have actually caught it, and there are ample examples of traditional OEMs missing things despite their longer validation cycles too.

On the other hand on the corporate side, I work for IBM now. The company has successfully remade itself repeatedly in the hundred years its been in business, and is currently in the middle of doing it yet again. While it has its own management problems, an unwillingness to take big risk and remake itself wholesale isn’t among them. Samsung (where I worked before this) had a similar tradition of “rethink everything (except your wife and family)” - which was a little weird but seemed to work well (Samsung also it fails the “not founder owned/operated” test, so may not be the best example). But I’d say Microsoft is also on the right track back to growth, but that one is too early to tell. But they’re definitely in recovery mode after stumbling.

It’s a taller order to ask the auto OEMs to do this, but there are signs they’re at least thinking in the right direction as most are talking about “transportation” now instead of “vehicles.”

And the vast complexity of the undertaking is a significant barrier to industry entry, so they’ll have a decent amount of protection from others who may try and enter the market (thinking Karma or something similar here). And then there’e the question of talent. Tesla, Apple, and Google can only poach auto executives if there’s somewhere to poach from.

GAH! I have GOT to stop spending my whole work day on here!

But you bring up a ton of good discussion points that are fun to think through and talk about.

Most of all, I hate to come off as anti-Tesla - Musk is clearly brilliant and the company is doing well despite (because of?) the overpriced stock. Fresh thinking is always a good thing, and disruption helps the consumer and the industry to move forward when it’s stuck - and we really do have Tesla to thank for that.

I bristle at calling everyone else stupid, which is the general sentiment here too often. It’s not stupidity - it’s caution bred of circumstances outside their control. But times are changing. Tesla has a lot to learn from the traditional OEMs, and that’s why they hire so many people from Detroit. But those OEMs have an even harder challenge learning from how Tesla is doing things to innovate better, loosen up, and learn how to compete better.

BLCKSTRM

> dsigned001 - O.R.C. hunter

BLCKSTRM

> dsigned001 - O.R.C. hunter

05/01/2016 at 02:46 |

|

Stumbled across something while I was working tonight.

I have friends in the press corps who have told me first hand that Tesla generally has quality problems, and I think most of us have read thins long those lines, but everyone has an anecdote about their friend with the Mercedes that was always in the shop.

My anecdote is my 1984 Toyota 4x4 Pickup, which had its engine replaced at least three times in the 6 years I owned it. So, I found Top Gear’s two episodes on the indestructability of that truck hilarious. Defies convention, doesn’t it?

Anyway, here’s the link. http://www.reuters.com/article/us-tes…

While Tesla has trimmed its average warranty repair cost per premium electric vehicle since 2014, it still spends more than twice as much as General Motors Co ( GM.N ) and Ford Motor Co ( F.N ), according to a Reuters analysis of company data.

Tesla’s warranty costs are also higher than those of Germany’s Daimler AG ( DAIGn.DE ), maker of Mercedes-Benz luxury cars.

Tesla and other auto makers don’t reveal specific figures for warranty costs per vehicle, but they do disclose vehicle deliveries, and total spending for warranty repairs and accruals, representing money set aside for future warranty repair work.

Last year, according to a Reuters analysis of data provided in the company’s annual report, Tesla spent $1,043 per vehicle on actual repairs and set aside $2,036 in warranty accruals to cover future repairs on the vehicles it sold in 2015. It trimmed warranty expenses by 17 percent from 2014 and cut warranty accruals by 34 percent.

Meanwhile, GM spent just $400 last year for every vehicle it sold on warranty repairs and set aside $332 for future work. Ford spent $429 per vehicle and set aside $308. Daimler spent $970 per vehicle and set aside $1,294.